Click and hold left mouse button to zoom in

Click and hold left mouse button to zoom in

Click and hold left mouse button to zoom in

Click and hold left mouse button to zoom in

Click and hold left mouse button to zoom in

ConveyorControl

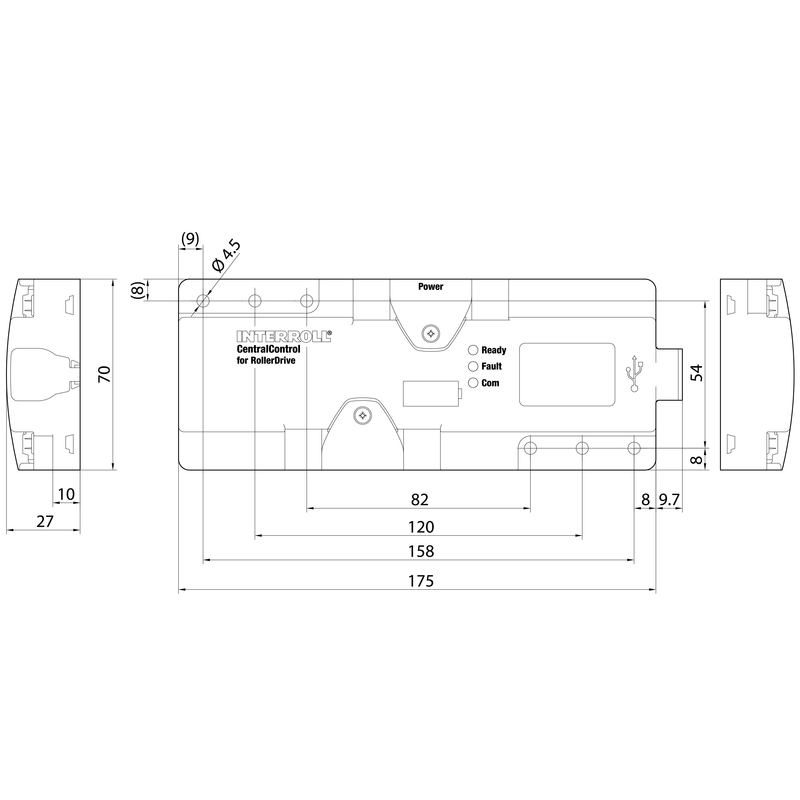

With CentralControl: zero-pressure accumulation conveying (ZPA) of many zones without connected PLC. Or ZPA with input from a PLC connected via digital inputs and outputs.With GatewayControl: zero-pressure accumulation conveying (ZPA) of many zones with input from a PLC connected via fieldbus. Or universal control (not just ZPA) with PLC connected via fieldbus.

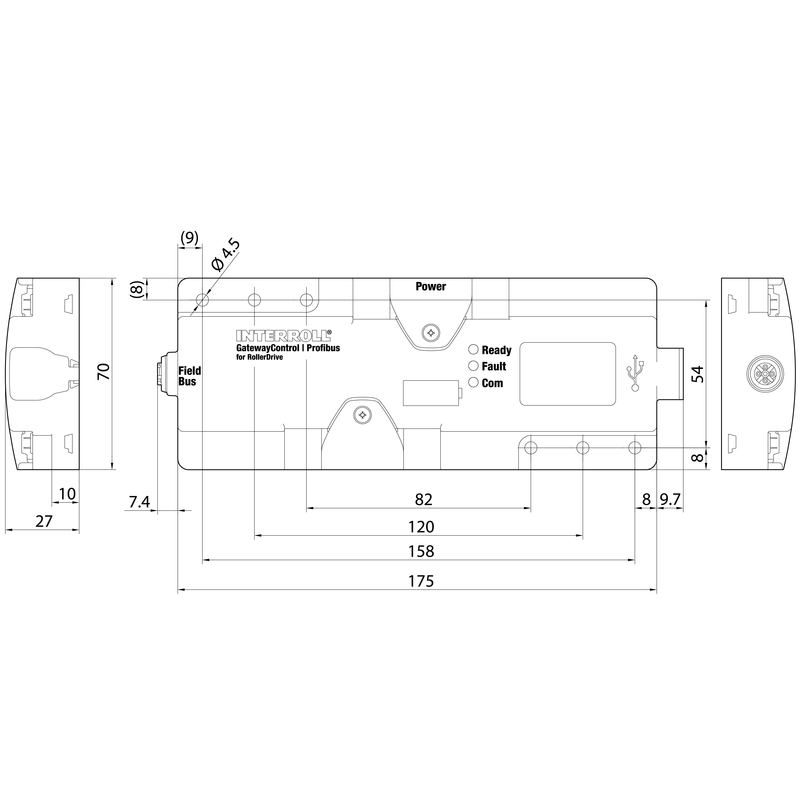

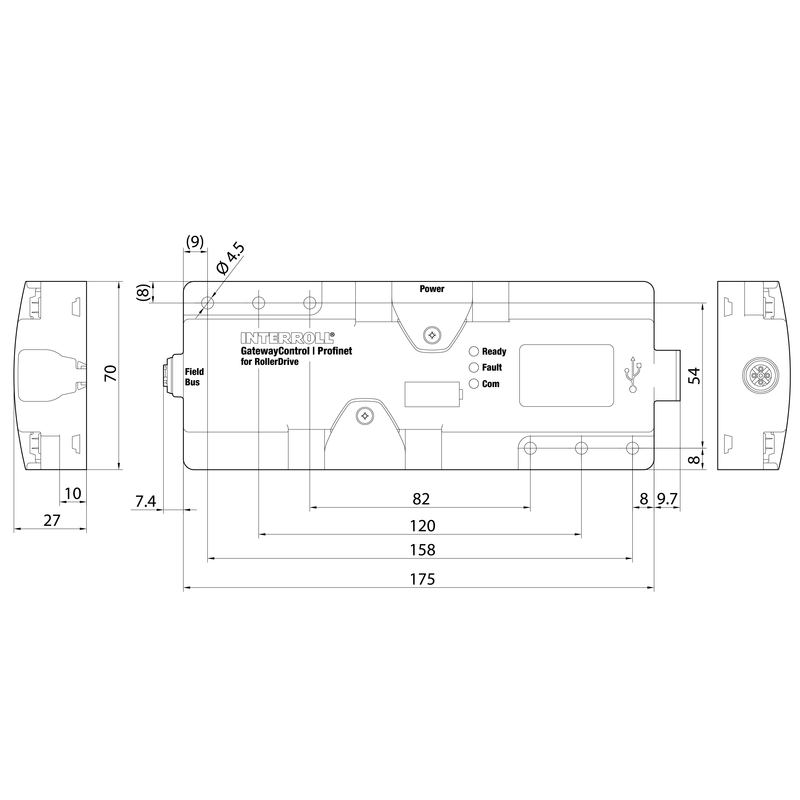

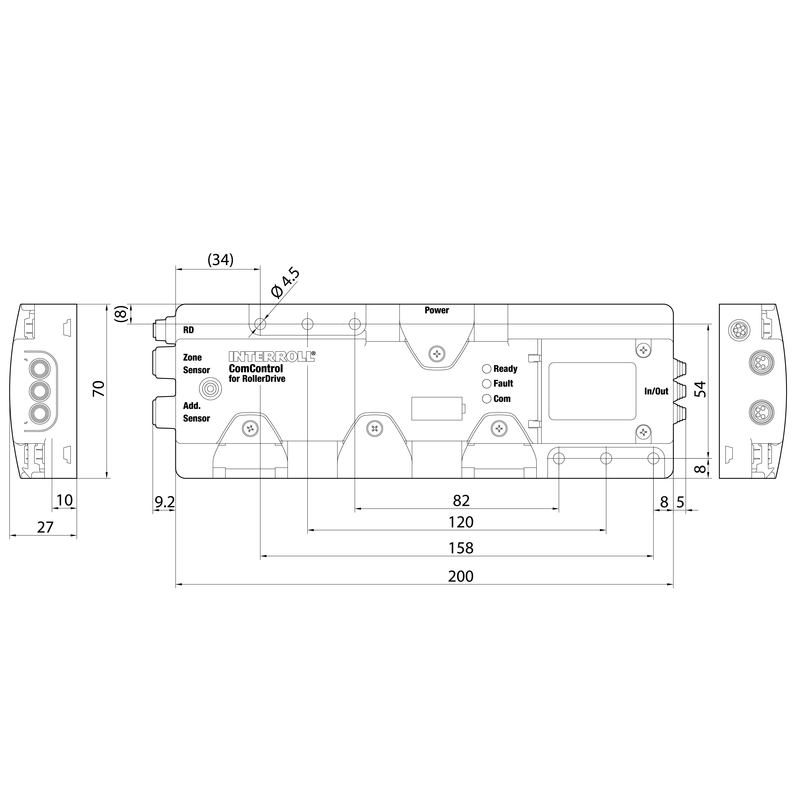

The ConveyorControl system includes the GatewayControl, the CentralControl, the SegmentControl and the ComControl (Possible applications).

Cost-efficient, commercially available flat cables are used for wiring the communication and voltage. All settings are made with a Windows-based software – the Configurator. The software simplifies addressing and enables GUI-supported parameter setting of up to 200 RollerDrive and sensors simultaneously. The configuration of an existing application can be read out from the controls and changed as needed.

The advantage is that the ZPA logic is included and does not have to be programmed within a PLC. The ConveyorControl system allows tracking materials and offers a large number of setting options and additional functions.

- Logic for zero-pressure accumulation conveying incl. initialization

- Communication via bus system

- Configurator allows the setting of (individually, in groups or all nodes): speed, direction of rotation, start and stop ramp of RollerDrive; sensor properties; timer; error handling; logic for single/train release

- Status display with LEDs

- Additional functions: running the conveyor empty, external start or stop signal

- Interface to PROFIBUS, PROFINET or EtherNet/IP

- Voltage limitation via brake chopper

- Plug & Play in case of replacements – no addressing or configuration required